Sustainable Construction

Lorem ipsum dolor...

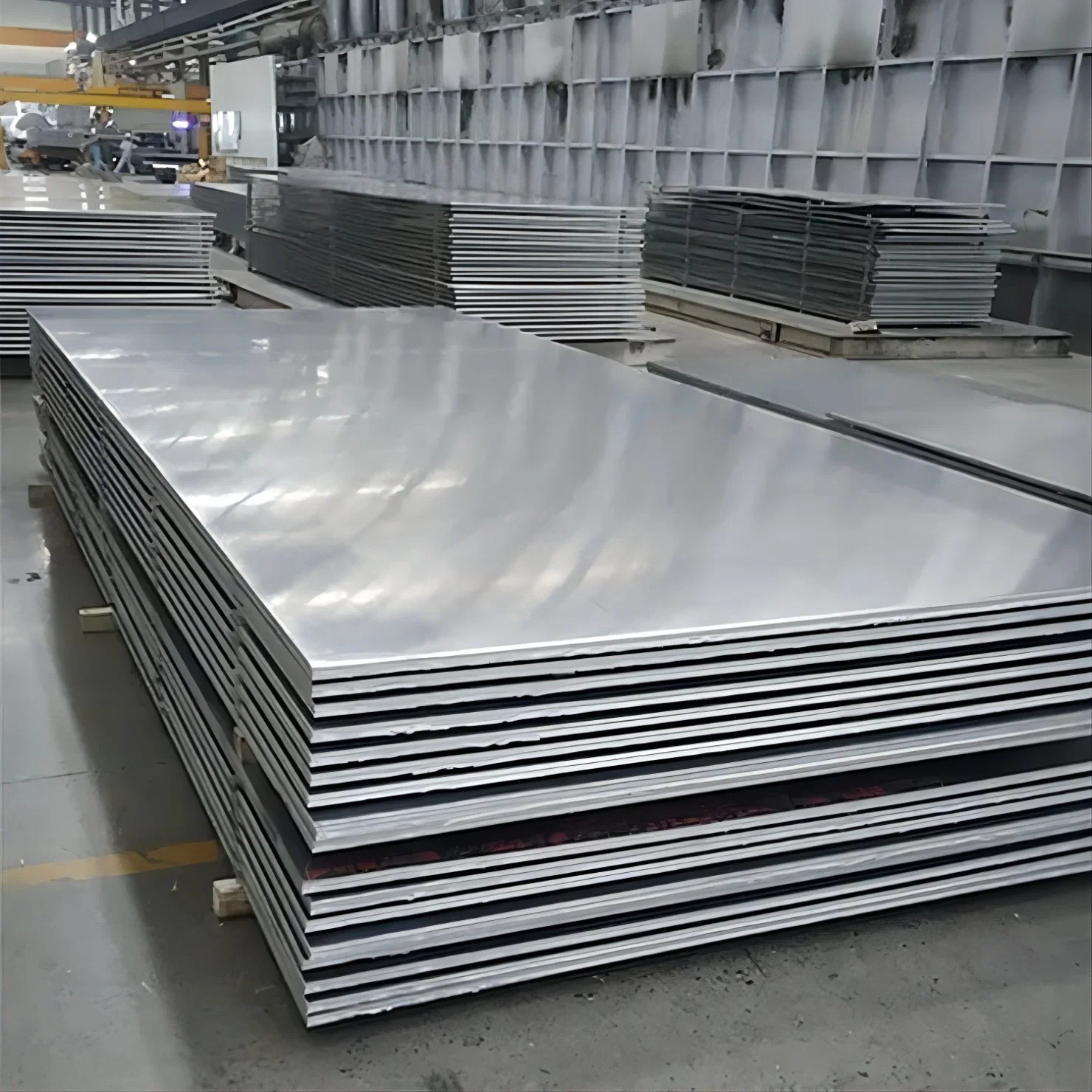

At Parshv Steels , we provide a diverse selection of steel plates to cater to various industrial needs. Our Hot Rolled Steel Plates are ideal for structural applications, while Cold Rolled Steel Plates offer a smooth finish and precise dimensions. For enhanced durability, our Galvanized Steel Plates feature a corrosion-resistant zinc coating, and our Stainless Steel Plates provide superior resistance to rust and high temperatures. Additionally, our Abrasion Resistant Steel Plates are designed for high-wear environments, ensuring exceptional strength and longevity in demanding applications.

Hot Rolled Steel Plates are produced through a high-temperature process, making them ideal for structural and industrial applications that require durability and strength. These plates are commonly used in construction, machinery, and large fabrication projects due to their ability to handle heavy loads and extreme conditions.

Cold Rolled Steel Plates are manufactured at room temperature, resulting in a smoother surface and tighter tolerances. They are perfect for applications requiring precision and a sleek appearance, such as in automotive parts, appliances, and high-end industrial components.

Galvanized Steel Plates are coated with a layer of zinc, providing excellent corrosion resistance. These plates are ideal for outdoor, marine, and industrial applications where protection against rust and environmental exposure is essential, such as roofing, fencing, and construction.

Stainless Steel Plates are known for their superior corrosion resistance, heat tolerance, and aesthetic appeal. They are widely used in industries requiring hygienic conditions, such as food processing, medical equipment, and architectural projects, as well as high-temperature environments.

Abrasion Resistant Steel Plates are specially engineered for high-wear environments, offering exceptional strength and longevity. These plates are commonly used in mining, construction, and heavy machinery, where resistance to abrasion, impact, and wear is crucial for performance and durability.

| Material | Thickness Range | Width Range | Length Range | Tolerance |

|---|---|---|---|---|

| Hot Rolled Steel Plate | 1.5mm to 200mm | 1000mm to 3000mm | 2000mm to 12000mm | +/- 0.5mm to +/- 3mm |

| Cold Rolled Steel Plate | 0.5mm to 3mm | 1000mm to 1500mm | 2000mm to 4000mm | +/- 0.05mm to +/- 0.5mm |

| Galvanized Steel Plate | 0.5mm to 5mm | 1000mm to 1500mm | 2000mm to 4000mm | +/- 0.05mm to +/- 0.5mm |

| Stainless Steel Plate | 0.5mm to 50mm | 1000mm to 2500mm | 2000mm to 12000mm | +/- 0.1mm to +/- 3mm |

| Abrasion Resistant Steel Plate | 3mm to 100mm | 1000mm to 3000mm | 2000mm to 12000mm | +/- 0.5mm to +/- 3mm |

| Patterned Finish | 2B Finish |

| Hairline Finish Plate | Mirror Finish Plate |

| No. 8 Finish | Brushed Finish |

| No.4 Finish | Embossed Finish |

| No. 4 – Brushed finish | 2R (Bright Annealed) Finish |

| No. 2B – Matte finish | No.8 – Mirror finish |

| Polished Finishes | Mirror Polished |