Sustainable Construction

Lorem ipsum dolor...

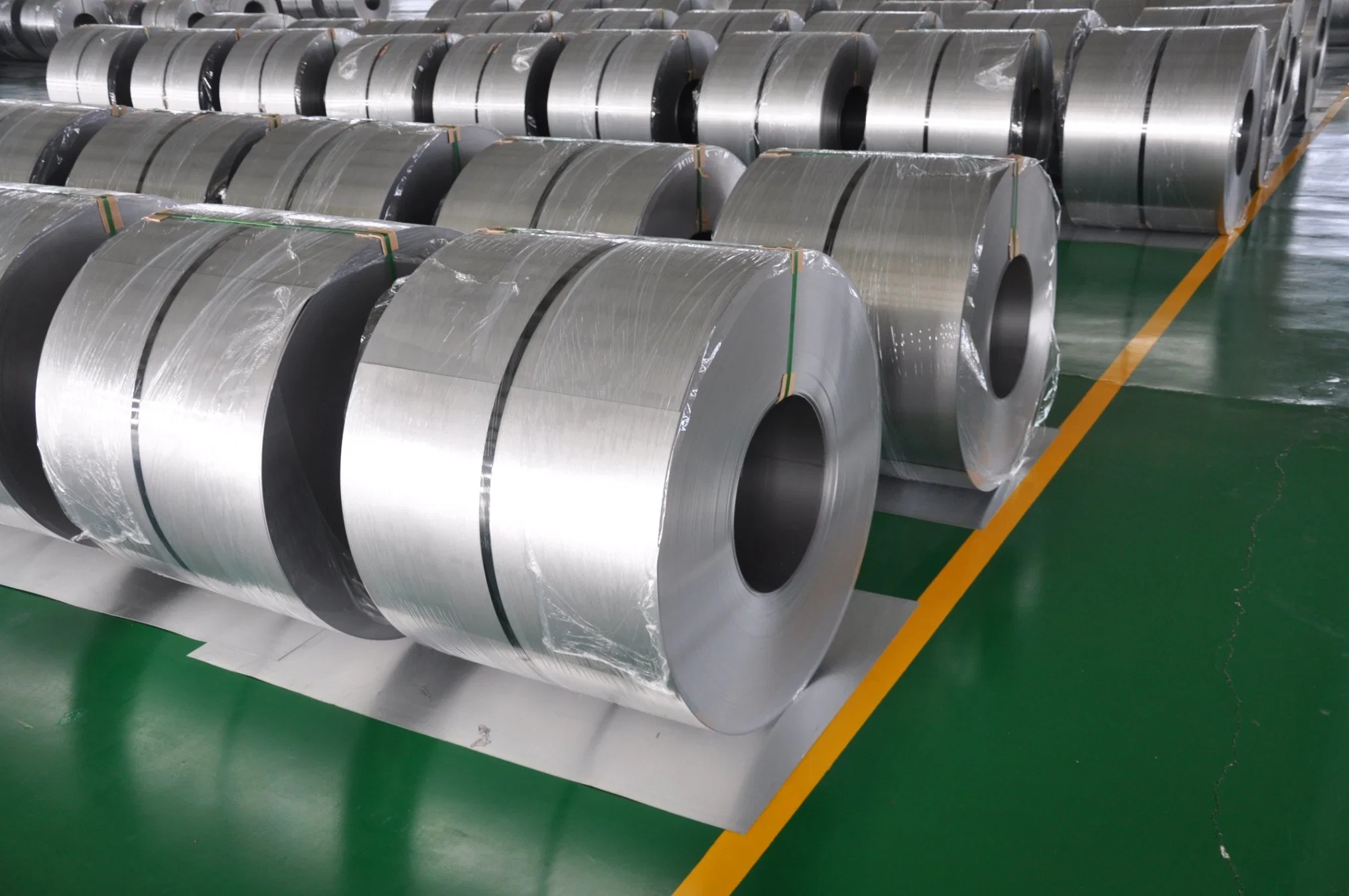

At Parshv Steels, Cold Rolled Steel Coils are manufactured at room temperature, resulting in a smoother surface finish and tighter tolerances compared to hot rolled coils. This manufacturing process enhances the material's strength, making it suitable for applications that require precision and accuracy, such as automotive parts, appliances, and high-end industrial products.

Cold Rolled Steel Coils are known for their excellent surface quality and uniform thickness, which make them ideal for applications where appearance is crucial. These coils offer higher strength compared to hot rolled products, while still maintaining good formability, making them perfect for stamping and other precision fabrication processes. They are widely used in industries such as electronics, machinery, and automotive manufacturing, where both aesthetic and mechanical properties are important.

Additionally, Cold Rolled Steel Coils provide enhanced strength-to-weight ratios, which contribute to efficient material usage in structural and load-bearing applications. With improved mechanical properties, including increased yield strength and hardness, these coils are used in a variety of demanding applications that require exacting specifications. Their smooth surface and durability make them an excellent choice for painted, galvanized, or otherwise finished surfaces.

| Thickness Range | Width Range | Inner Diameter | Outer Diameter | Tolerance |

|---|---|---|---|---|

| 0.3mm to 3mm | 1000mm to 1500mm | 508mm or 610mm | Max. 2000mm | +/- 0.05mm to +/- 0.5mm |

| Patterned Finish | 2B Finish |

| Hairline Finish Plate | Mirror Finish Plate |

| No. 8 Finish | Brushed Finish |

| No.4 Finish | Embossed Finish |

| No. 4 – Brushed finish | 2R (Bright Annealed) Finish |

| No. 2B – Matte finish | No.8 – Mirror finish |

| Polished Finishes | Mirror Polished |